From POWER Magazine | 08/01/2011 | Dr. Robert Peltier, PE

Automatic Systems Inc. supplied the fuel- and material-handling equipment and was responsible for its installation.

Kansas City Power & Light (KCP&L) began engaging stakeholders in 2003 to develop consensus on a regional energy plan designed to balance customers’ desire for low electricity costs with system reliability needs and environmental requirements. The culmination of that plan was the completion of Iatan 2, which entered service in August 2010. For executing an innovative energy plan that reduced overall fleet emissions, ensuring the region’s future electricity supply, and completing an approximately $2 billion project in time for the summer 2010 peak load by using innovative contracting and project controls, KCP&L’s Iatan 2 is awarded POWER’s 2011 Plant of the Year Award.

KCP&L, headquartered in Kansas City, Mo., serves about 820,000 customers in western Missouri and eastern Kansas. Great Plains Energy Inc. is the holding company of Kansas City Power & Light and KCP&L Greater Missouri Operations Co. (GMO, the former Aquila, purchased in July 2008). However, KCP&L is the brand name used to represent both of these utilities.

KCP&L has an installed capacity of approximately 6,700 MW. Its coal-fired Iatan Station, located about 30 miles northwest of Kansas City, near Weston, Mo., features the recently renovated approximately 700-MW Unit 1 and the 850-MW (net) Unit 2, which went into service in August 2010 (see Table 1). Iatan 2 (Figure 1) was KCP&L’s first new baseload plant in nearly three decades. In addition, this milestone marked the finale of KCP&L’s Comprehensive Energy Plan (CEP), initiated seven years earlier. The plant is named after Iatan, a chief of the Otoe tribe that fought battles with the Comanche (also called Iatan) around 1800.

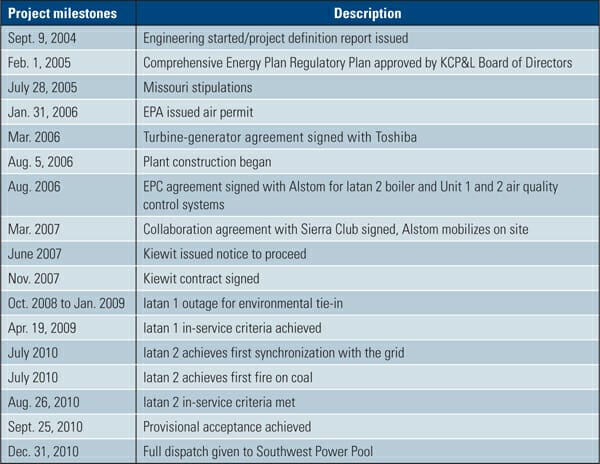

Table 1. Key milestones for the Iatan 2 project. Iatan 2, erected over a five-year period, was one of the largest and most complex construction projects in Missouri and KCP&L history. Source: KCP&L

1. Latest and greatest. The Iatan Generating Station is located on the banks of the Missouri River in western Missouri. Commercial operation of Iatan 2 in December 2010 added 850 MW to the approximately 700 MW produced by Iatan 1. Iatan 2 was the first new baseload power generator installed by KCP&L in nearly 30 years.The PlanIn 2003, KCP&L began updating its energy development plans to meet expected regional demand growth for itself and its project partners. The goal of the CEP was to add needed baseload capacity while lowering the utility’s overall emissions by strategically adding renewable energy projects and investing in energy efficiency, a synergistic package of improvements benefiting all stakeholders. KCP&L’s fuel mix is about 80% coal, 17% nuclear (Wolf Creek Generating Station was the last baseload generation built, in 1985), 2% natural gas and oil, and 1% wind. Specifically, the CEP proposed development of about 100 MW of wind energy, upgrading the air quality control equipment on Iatan 1, a selective catalytic reduction (SCR) system for LaCygne 2, a number of transmission and distribution system upgrades, a demand-side management program designed to help ratepayers reduce consumption, and the development of Iatan 2. William Downey, executive vice chairman and the company’s senior executive on the project, noted in an interview with POWER, “When Iatan 2 was being built, it was one of the largest and most complex construction projects in KCP&L and Missouri history. Because of the benefits it brought to this region, it was a bright spot in a bleak economic time.” Downey also noted that portions of the CEP proposed financial processes that would allow the utility to maintain credit metrics throughout the construction process given that Missouri regulations do not allow construction work in process to be added to the rate base. The KCP&L cost analysis concluded that, from a baseload generation perspective, coal-fired generation still enjoys a significant cost advantage over other generation technologies, even when considering the cost of meeting challenging emissions-reduction goals. Inclusive Resource PlanningMany utilities approach resource planning as a euphemism for building a new plant, regardless of the public’s support. KCP&L’s CEP took a radically different approach to gaining acceptance: It took the story directly to the public. The theme of the message was, “This is how we see our building evolving over the next decade or more, and here is our strategy for balancing projected demand for electricity with a sustainable environment.” KCP&L hosted community workshops to explain and discuss all aspects of the plan, listen to consumers and their concerns, and feed that information back into the CEP development process. Similar discussions were held with regulators and Wall Street financial representatives, who critiqued the plan and suggested improvements that would reduce risk to ratepayers and stockholders. Michael Chesser, chairman and CEO, commented on the uniqueness of this approach to resource planning: “In 2004, KCP&L recognized the need to generate additional electricity in order to meet growing demand. We took a new approach to figuring out how we would do this. We decided to collaborate with the community, and the outcome was the Comprehensive Energy Plan. Iatan 2 is the cornerstone of the Comprehensive Energy Plan, which provides affordable, reliable, and sustainable electricity for decades to come.” The CEP was approved by Kansas and Missouri regulators in 2005 with the plan that Iatan 2 would be online in the summer of 2010. The uniqueness and efficiency of the KCP&L collaborative planning process was soon recognized by the entire power generation industry. For establishing the CEP planning process, The Edison Electric Institute (EEI) awarded KCP&L its 2007 Edison Award for meeting the “region’s growing demand for clean, affordable energy by developing new, clean energy sources, making proactive environmental and infrastructure improvements and creating innovative energy efficiency and demand-response programs.” The EEI citation went on to say that “KCP&L has worked with a wide variety of stakeholders, establishing true partnerships within its communities to create political and regulatory environments that have allowed the company to deliver on its promises.” This isn’t to say that KCP&L’s early planning process didn’t meet with strong opposition. For example, Iatan 2 was sailing through the regulatory approval process when the Sierra Club and Concerned Citizens of Platte County intervened in the Prevention of Significant Deterioration permit process in late September 2006. After several procedural moves, KCP&L and the other litigants negotiated an agreement that fulfilled the public’s desires, as expressed in the CEP, and addressed the interveners’ environmental concerns while ensuring that the utility would be able to meet its expected demand growth. The Collaboration Agreement, signed in March 2007, gained KCP&L’s agreement to offset an estimated 6 million tons of CO2 emissions each year, add 100 MW of wind power by 2010 (which was already under development), and add another 300 MW of wind supply by 2012—the amount of wind capacity the utility believed was prudent given wind’s variability. The agreement also included investment in energy-efficiency projects to reduce demand by 100 MW immediately, plus another 200 MW reduction by 2012. (KCP&L implemented 15 residential and commercial customer energy-saving pilot programs to meet this goal.) Mobilization of the construction site began shortly after this agreement was signed. The Sierra Club described the result of the negotiation “a groundbreaking agreement that can serve as a model for environmental groups and utilities working together.” You may recall City Water, Light & Power, the municipal utilities agency of the City of Springfield, Ill., negotiated a similar agreement to allow its Dallman 4 project to move forward. Dallman 4 was POWER’s 2009 Plant of the Year (see the August 2009 issue in our online archives at www.powermag.com). The price tag for all the projects included in the CEP was about $3 billion and covered a variety of strategic investments:

Output from the 850-MW Iatan 2 is owned by a consortium of utilities and power distributors. KCP&L and its affiliate KCP&L GMO own roughly 73% of the new plant; Empire District Electric owns 12%; Missouri Joint Municipal Electric Utility Commission owns 11.76% (equivalent to 100 MW); and Kansas Electric Power Cooperative owns 3.5%. KCP&L and GMO own 88% of Iatan 1. KCP&L is the plant operator and responsible for routine maintenance. Work the PlanApproval of the CEP by both the Missouri Public Service and Kansas Corporation Commissions cleared the regulatory road for construction of Iatan 2, although KCP&L had began construction of the environmental upgrades for Iatan 1 the previous August. Construction started on Iatan 2 in September 2007. Earlier that year, KCP&L had awarded a fixed-price contract to Alstom Power to engineer, design, and construct the boiler island, including the air quality control system (AQCS) for both units. The steam turbine was purchased from Toshiba. Burns & McDonnell was retained to provide engineering design services for both projects (Table 2).

Table 2. Major contractors and equipment suppliers to the Iatan 2 project. Source: KCP&L

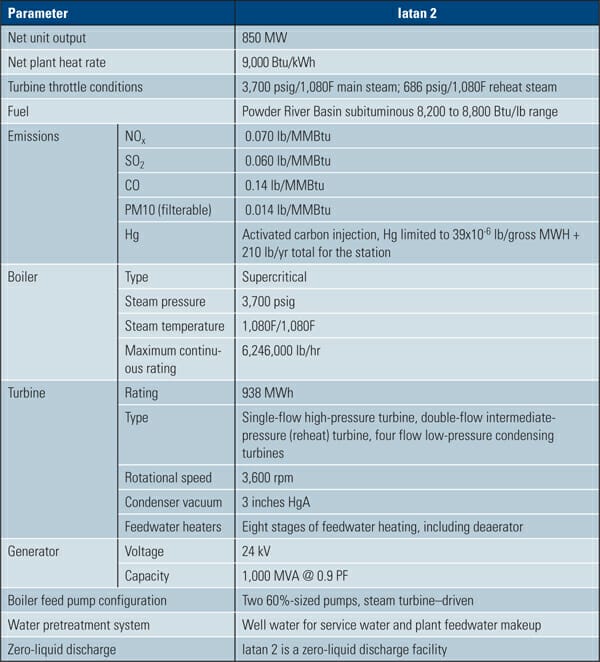

The supercritical Iatan 2 boiler, Alstom’s largest sliding pressure boiler in the U.S., was designed to burn low-sulfur Powder River Basin coal with low-NOx tangential burners. “Iatan 2 will be approximately 10% to 12% more efficient than a typical plant built in the 1970s,” says Burns & McDonnell project manager Bob Reymond. “The state-of-the-art emissions control systems will remove about 98% of sulfur dioxide from the exhaust.” The post-combustion AQCS begins with an SCR, fabric filter, and wet flue gas desulfurization (wet FGD). Activated carbon injection (ACI) was also added to the AQCS suite of equipment for mercury emissions reductions. The permitted levels of mercury emissions are based on site emissions, thereby giving operators some discretion in how much activated carbon is injected into each unit (Figure 2).  2. Duplicated design. The design of the air quality control systems for the two units was very similar. On Iatan 1, the selective catalytic reduction (SCR) system was placed away from the unit because of retrofit space constraints; for Iatan 2, the SCR system was part of the integral design. Otherwise, the same catalyst type and size was used, and both boxes are able to hold four layers, although only two layers are currently used on each unit. Courtesy: KCP&L For simplicity of common operating practices and cost-effective purchasing, the entire post-combustion AQCS for Iatan 1 is virtually identical to that of the new Iatan 2. Today, the NOx emissions of both units are 53% lower, and SO2 emissions are 74% lower, than those of only Iatan 1 prior to the AQCS upgrades. Using high-efficiency supercritical combustion technology also contributed greatly to the utility’s CO2reduction goals, as higher combustion efficiency means less CO2 is produced per ton of coal consumed. KCP&L continues to make focused investments in initiatives with the goal of improving the operating efficiency of its coal fleet 3% by 2013. Iatan 2’s sliding pressure boiler mode of operation also helps the plant meet the design goal of being capable of performing daily load swings from 40% to 100%. Of particular interest in the project technical specifications (Table 3) are the main and reheat steam temperatures, which are both 1,080F—more aggressive than the typical 1,050F of similar supercritical plants. Recent reports from the plant confirm that plant operation has been very stable with these near-state-of-the-art steam temperatures.

Table 3. Key Iatan 2 performance parameters. Iatan 2 uses a supercritical steam generator and a system of air quality control devices to keep air emissions low. Source: KCP&L

Unique Contracting ApproachOnce the long-lead equipment purchases were completed (over $1 billion by August 2006), KCP&L made inquiries with experienced power industry contractors to assume the project lead but found little interest in constructing the plant on a turnkey basis. The challenge for contractors at the time was the rapidly increasing cost of commodities such as copper and steel plus nationwide high demand for limited journeyman construction talent for constructing new coal plants and retrofit AQCS systems. KCP&L decided to proceed with the project using a multi-prime approach combined with aggressive purchasing processes to limit the risk of future price increases. In essence, KCP&L would assume the responsibility and risk of the general contractor by using seven or eight smaller contractors to complete the balance-of-plant work on Iatan 2. Alstom mobilized onsite to begin its work on boiler erection shortly after signing of the Collaboration Agreement. Fortuitously, the cancellation of another large project opened up the work schedule of Kiewit Power, a very experienced prime contractor in the power industry. Kiewit Power was subsequently selected as the contractor responsible for all balance-of-plant construction, construction interface with the boiler island, and assembly of the steam turbine generator. Plant Systems’ DesignThe design of several plant systems deserves particular note given their unique approach for solving sticky problems, often with a simple solution. Coal- and Ash-Handling Systems. Coal is delivered to the plant by BNSF railroad by one or two unit trains each day. The coal is dumped through a single rotary car dumper and delivered by a stacker reclaimer, a system that has proven its reliability since Iatan 1 was put into service. The design of Iatan 2 added a parallel stackout pile with the capacity to handle the coal delivered by two unit trains. Also added was a second delivery conveyor to Iatan 1 to match the redundant conveyors installed on Iatan 2. When operating at full load, each unit consumes about 10,000 tons a day, the equivalent of about one and one-half unit trains each day. The conveyors are fully enclosed and have a considerable number of dust collection stations, including the transfer towers (Figure 3). Automatic Systems Inc. supplied the fuel- and material-handling equipment and was responsible for its installation.

|

Plant of the Year: KCP&L’s Iatan 2 Earns POWER’s Highest Honor was last modified: March 1st, 2019 by