VDLs (Vertical Drop Lifters) are a safe, strong, and reliable solution used to move products and carriers between elevated delivery lines and floor level production lines or to transfer products between different systems and processes.

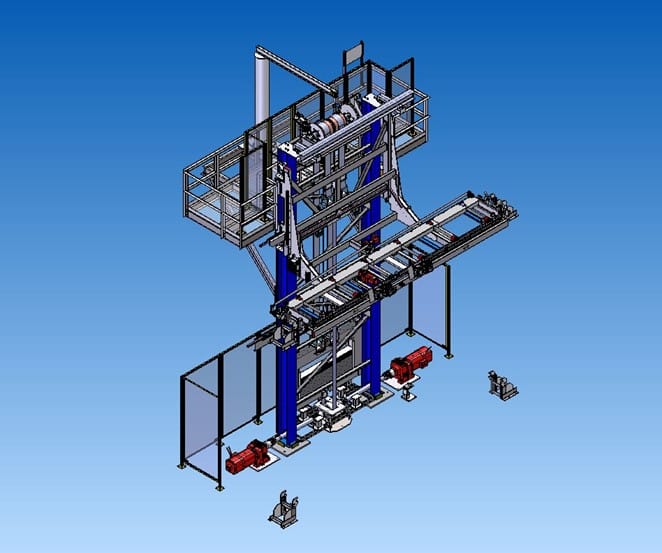

With vertical travels of over 30 feet and capacities of over 16,000 lbs., ASI’s standard VDLs are customizable to your material handling challenges and adaptable to work with any type of conveyor system including EMS (Electrified Monorail Systems), Friction, Power & Free, Skid and Skillet.

On board PLC smart controls with VFDs (variable speed drives) paired with encoders, coded rail and torque proving technology provide for safe, precise, and repeatable positioning and load control. Available standby drives provide an added layer of reliability.

2-post VDLs optimize plant floor space while 4-post VDLs provide the highest capacity and stability.

.